Author:Dafon Kerbstone Machine FROM:Stone Machine Manufacturer TIME:2024-05-10

Briefly discuss common uses for concrete blocks in construction projects.

Concrete is the most widely used and consumed building material in the world today. Its application fields include construction engineering, highway engineering, bridge and tunnel engineering, water conservancy engineering, and various special structures. The wide range of applications is due to the following significant advantages of concrete:

1. Abundant raw materials, low prices, and simple production processes

The raw materials of concrete are widely available, easy to obtain, and cheap. Its main components are cementing materials (cement), aggregates (sand and gravel) and water. There is no need for complicated processes during the production process. The raw materials only need to be prepared in proportion, and can be made after mixing, vibrating, forming and curing. The production process is simple and the cost is low, making it a highly cost-effective building material.

2. High compressive strength and good durability

Concrete has excellent compressive properties and can withstand huge pressure, making it an ideal material for various load-bearing structures. In addition, concrete also has good durability and can resist wind and rain erosion, acid and alkali corrosion, etc., extending the service life of the building.

3. Wide range of strength levels and strong adaptability

The strength grade range of concrete is very wide, from low-strength concrete to ultra-high-strength concrete, which can meet the different strength needs of different engineering projects. At the same time, various admixtures or other materials can be added to concrete to meet specific performance requirements and adapt to different environments and usage conditions.

To sum up, concrete has become the well-deserved "King of Building Materials" with its abundant raw materials, low price, simple production process, excellent performance and wide adaptability.

Introduce the concept of concrete block cutters and their purpose.

The concrete block cutting machine is a special equipment specially used for cutting concrete blocks and plays an important role in construction, engineering, and other fields. It can accurately cut large concrete blocks into required sizes and shapes to meet different construction needs and improve construction efficiency and block accuracy.

Concrete block cutting machine: a universal helper in the construction field

Concrete block cutting machines play an indispensable role in construction, engineering, and other fields with their efficient and precise cutting capabilities. Its wide range of application areas include:

A. Manual Block Cutters

The manual concrete block cutting machine is a cutting tool with a simple structure and easy operation, suitable for cutting small concrete blocks. Its low price and easy portability make it an economical and affordable choice for home decoration, small building construction and other scenarios.

advantage

Portability: The manual cutting machine has a simple structure, small size and light weight, making it easy to carry and transport, and is suitable for use in narrow spaces or on-site operations.

Economy: Manual cutting machines are low-priced, low-maintenance, and cost-effective, making them suitable for users with limited budgets.

Easy to operate: The manual cutting machine is easy to operate, and even beginners can master it quickly.

Safety: The manual cutting machine has no power drive, runs smoothly, has low noise, and is relatively safe.

Shortcoming

Limited cutting depth: Manual cutters usually have a smaller cutting depth and are not suitable for cutting large or thick blocks.

Requires effort: Manual cutting requires continuous power from the user and may cause fatigue when working for long periods of time.

Cutting accuracy: The accuracy of manual cutting is usually not as good as that of power cutting machines, and errors may exist.

Applicable scene

Manual concrete block cutting machine is suitable for the following scenarios:

Home decoration: used for cutting small wall tiles, floor tiles, etc.

Small building construction: used for cutting small blocks, repairing walls, etc.

DIY enthusiasts: For making small concrete crafts.

B. Automatic Concrete Block Cutters

The automatic concrete block cutter is an efficient building construction tool used for cutting concrete blocks, bricks, and other materials. It is driven by a motor and can realize automated cutting operations, which has significant advantages over traditional manual cutting.

Traditional concrete block cutting relies on manual operation, which is inefficient and the cutting accuracy is difficult to guarantee. The automatic concrete block cutting machine, with its powerful power and intelligent control system, can bring the following significant advantages:

Faster: The concrete block cutter is driven by an electric motor, and its cutting speed is far faster than human operation, greatly improving work efficiency.

Higher precision: The automatic block cutting machine is equipped with a guide device and an automatic feeding system to ensure straight and smooth cutting, effectively reducing cutting errors and material waste.

Deeper cutting: The concrete block cutter can provide greater cutting power and easily handle thicker or harder concrete blocks to meet various cutting needs.

Compared with manual cutting, automatic concrete block cutters make the cutting process easier and more efficient and can achieve more precise cutting results, thereby reducing material loss and improving construction quality.

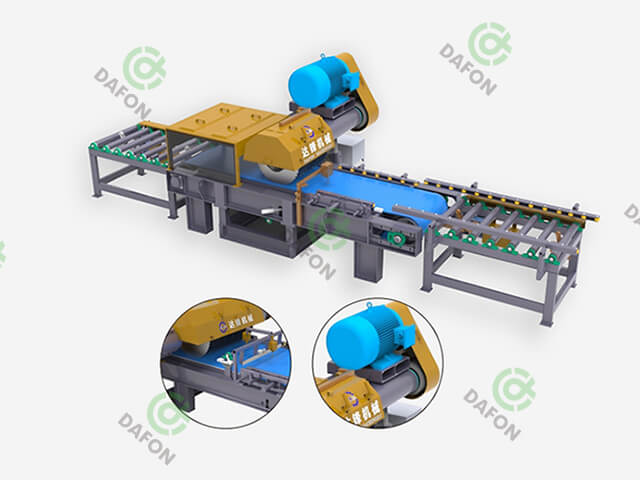

Dafon Design and manufacture Concrete Block Cutter Processing Line

The Concrete Block Cutter Processing Line is an efficient cutting equipment suitable for cutting concrete blocks. It adopts advanced cutting technology and automated control system, and has the characteristics of fast cutting speed, smooth incision and high precision. The assembly line can achieve continuous operation, is simple to operate, safe and reliable. In addition, the equipment uses environmentally friendly materials, has the advantages of low energy consumption and low noise, making it an ideal choice for modern block and building material processing.

When choosing a concrete block cutter, there are several factors to consider to ensure that the equipment you choose will meet your needs. Here are some key factors you should consider when choosing a concrete cutter:

1. Cutting requirements

Cutting size: Make sure the cutter can cut the largest size concrete block you need.

Cutting depth: Confirm that the maximum cutting depth of the cutting machine can meet your processing needs.

2. Power supply type

Electric: suitable for larger-scale projects, but needs to be connected to a power source.

Pneumatic: Suitable for working environments without power supply but with air source.

3. Power and efficiency

Motor Power: Choose a high-power motor for faster, more efficient cutting.

Cutting efficiency: Consider the cutting speed of a cutter or the time it takes to complete a standard task.

4. Operation method

Manual: Suitable for small-scale operations or delicate work, but requires more physical labor.

Electric automatic: It can improve efficiency and reduce labor intensity, suitable for large-scale projects.

5. Brand and price

Well-known brands usually provide higher quality and after-sales service, but the prices are also relatively high.