Price:

Model Number: MB131264

Power: 55KW

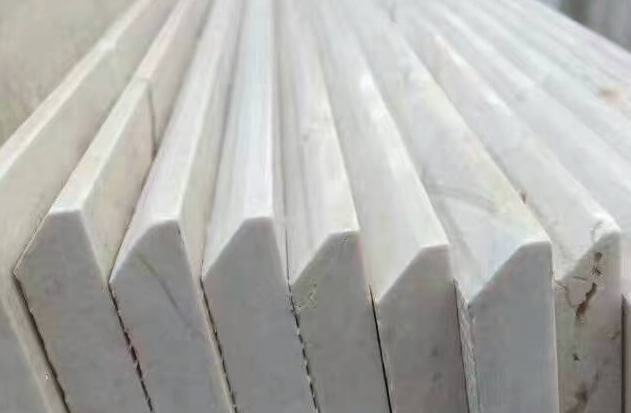

Application: Art & Craft, Stone Industry

Weight: 5500KG

Brand Name: DAFON

Certification: CE, ISO

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

granite polishing grinder Features:

1.granite polishing grinder 13 heads Three pillars

2.Electric adjustment motor swings from 45°to 90°arbitrarily, electric adjustment motor moves back and forth, lifts

3.The grinding wheel of granite line polish machine adopts water grinding disc, equipped with snail buckle joint, frequency conversion speed regulation, No. 1 and No. 2 flat forming motors 5.5 kW, No. 3 and No. 4 motors 4.5 kW, No. 5, 6, 7, 8, and 9 motors 3 kW (No. 3-9 motors are placed vertically, the bottom of the processing is flat and polished, and the front of the stone can be moved to process the corners, and the edge grooves are polished),

the No. 10 motor is back-cut 7.5 kW (the No. 10 motor is placed at 45 degrees, and the diameter is 300 saw blades processing rock slab, stone material and other materials back cut), chamfering motor, No. 11 motor 4.5 kW, No. 12, No. 13, No. 14 motor 3 kW (No. 11-14 motor 45 degrees inclined, 45-90 degrees Arbitrary electric angle adjustment with No. 1 and No. 2 forming motors for processing 1/2 round, 21st side and other Roman edges), front chamfering of various processed stones, and various flat stones can be ground according to different sizes and thicknesses of the calibration + right Angle bottom edge, pull groove with polishing, pull groove with polishing, thickening straight edge light, straight bottom edge at 45° chamfering, small R round belt side polishing, grooving polishing, Begonus corner back cutting, saw blade without seamless back cutting, kicking line, anti-skid groove, French edge, straight edge, edge and corner forming polishing, The rough grinding, fine grinding, and polishing processes are completed at one time. The brightness after processing is higher than that of the bright cutting of the board surface. The back cut and the bottom belt are polished at one time.

4.The structure is advanced and reasonable. The front and back of the motor can be adjusted electrically to avoid manual wheel change slow speed, many links and complex operators, workers are unwilling to change wheels, slow wheel changes appear. High precision, fast efficiency, easy operation, simple maintenance. During the grinding process, the feed speed and progress can be adjusted electrically by pressing the lift switch. The maximum amount of processing is 4m/min. The normal use of the machine is equivalent to the workload of 15 persons in the normal stone processing, and the process defects caused by the workers during processing are eliminated.

granite line polish machine Technical parameters:

|

Feed Output Speed |

1m-4m/min |

|

The Minimum Processing Size of Stone |

10-80 mm x 80mm |

|

Total Power |

55KW |

|

Body Weight |

5500KG |

|

Boundary Dimensions |

8200mm x 1400mm x 2000mm |

Country: Kuwait Type : 4 +1 axis bridge cutter Client's Background: The client is an engineering contracting company located in Kuwait, mainly engaged in interior and exterior de...

Not long ago, we received an inquiry from an Indian customer, Mr. G. He was looking for a stone splitter that would help him increase the efficiency of his marble cutting business. After s...

Specification: Name Unit DFQ-W(5+1)450 DFQ-W(5+1)600 Blade diameter mm Φ 350~450 Φ 450~600 Maximum processing size(L*W*H) mm ...

Introduction 4+1 Axis Bridge Cutter is based on the 4axis bridge cutter machine and adds an engraving head that is suitable for drilling or cutting granite, marble, and quartz stone counte...

The bridge saw machine adopt cast iron on the main part of machine body ensure stability while cutting The cutting speed is controlled by inverter to achieve stepless adjustment, the head mo...