Price:

Model Number: DFMJ-16C-24C

Power: Depends on heads no.

Application: stone/marble/granite

Weight: Depends on head quantity

Brand Name: DAFON

Certification: CE, ISO

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Intorduction:

A marble granite stone polishing machine is suitable for polishing Granite slabs or strips. Use the PLC system and liquid crystal display screen menu to offer intelligent control. Establish Auto-dodging function and shape memory function. allocation of the abrasive consumption equipment. which has high automation operation and low labor strength. Allocation of the flexibility Resin polishing heads. Prominent improvement in the polishing efficiency and polishing quality and greatly reduced abrasive consumption. Using the most advanced high-quality construction, rational structure. high stability and efficiency and energy-saving operation. The power movement of polishing heads using the spread-allied set improves slab flatness, reduces movement consumption, and enhances the longer working life. We can do the machines according to the client's requirements, like the number of heads, processing width, and length.

Feature:

Country: Saudi Arabiain Type: Multi Blade Stone Bridge Saw Client's Background: A specification slab stone processing enterprise in Saudi Arabia is mainly engaged in the prel...

Thismachineusesbigspanbridgestructure.Thecrossbeamandsidebeamsaresealedbyoilimmersionguideway,thelubemakethinoilfilmbetweenchanneledrailanddrivingblock,andputtingthesideseamprotectorcanmaket...

Specification: Name Unit DFQ-W(5+1)450 DFQ-W(5+1)600 Blade diameter mm Φ 350~450 Φ 450~600 Maximum processing size(L*W*H) mm ...

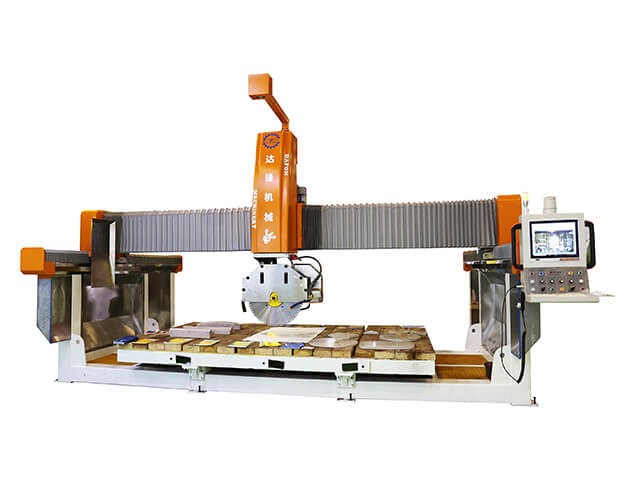

Introduction: 5 axis CNC bridge cutter is for special shape and high accuracy slab cutting, especially for polygonal, triangular sector countertops, oval, rhombus, round, horse belly edge, ...

Introduction: 5 Axis w ater Jet cutting m achine consists of four parts: a cutting platform, a CNC operating system, a high-pressure system, and an automatic water jet sand feeding syst...