Price:

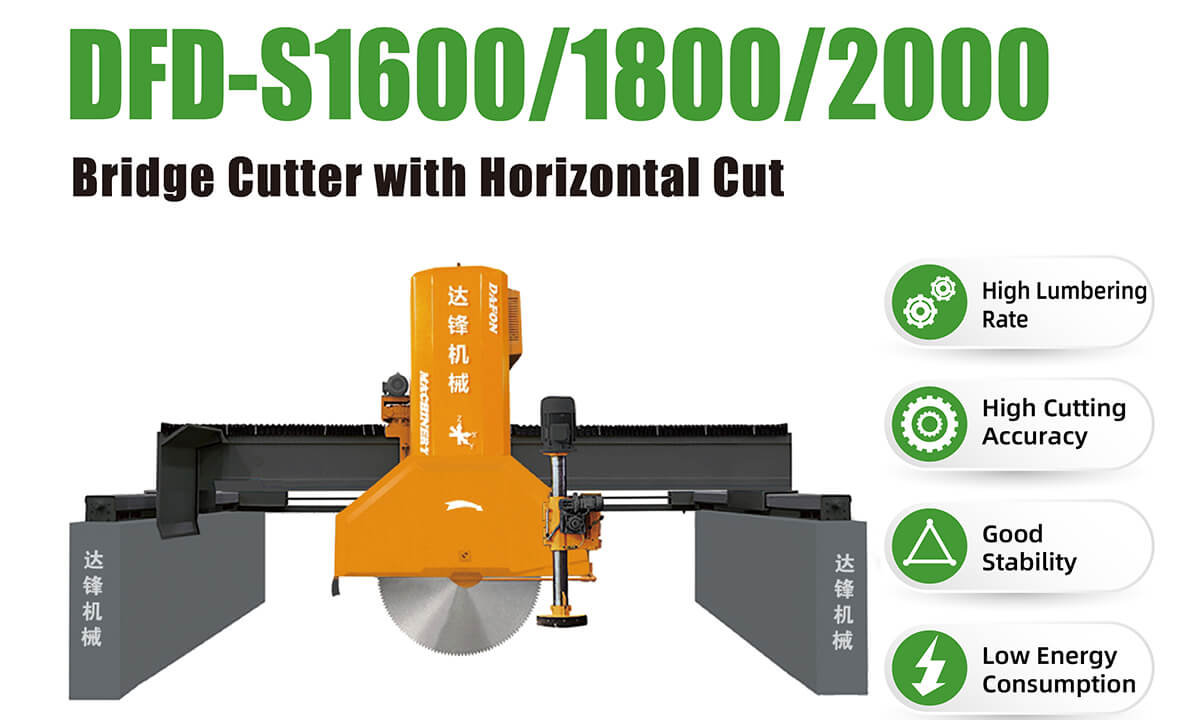

Brand Name: DAFON

Certification: CE, ISO

Model Number: DFD-S1600/1800/2000

Power: 75/90KW

Weight: 13000kg

Application: Art & Craft, Stone Industry

Place of Origin: CHINA.

Trading Method: FOB/CIF/EXW Xiamen Port

Minimum Order Quantity: 1 SET

Delivery Time:90 Days

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Introduction

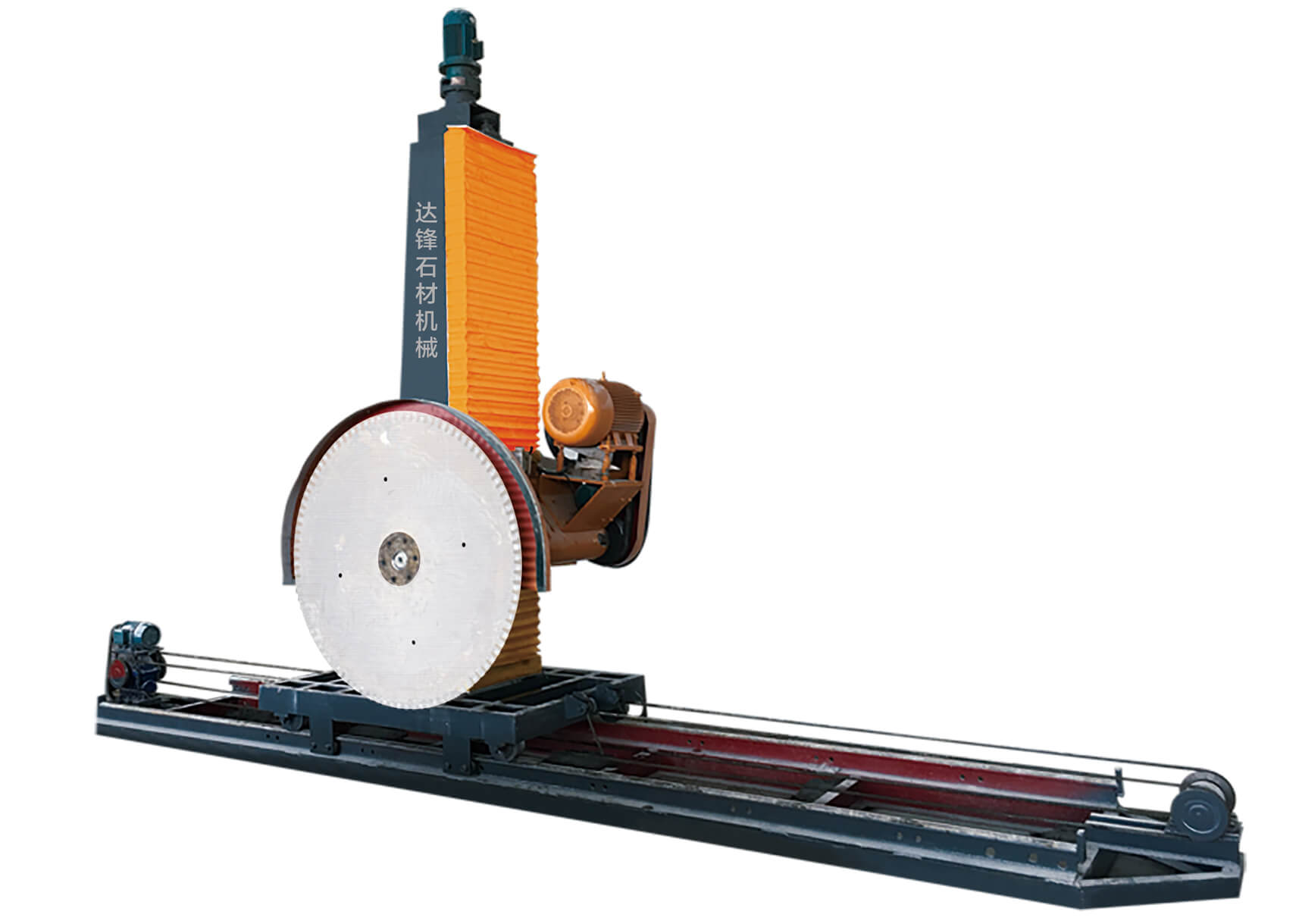

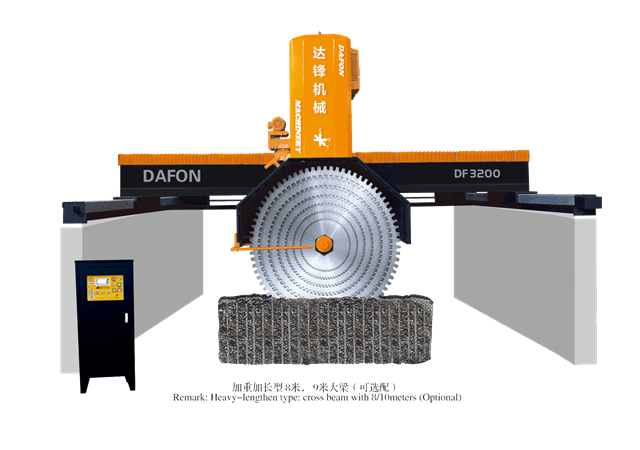

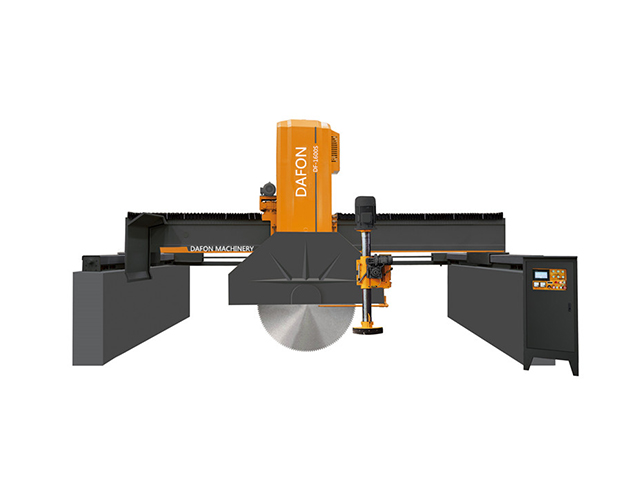

This equipment is based on the gantry big cut reasonably increase a group of horizontal knife cutting, horizontal knife can be turned to one side, so that the machine takes into account the function of ordinary bridge type combination saw, free from manual unloading of the board trouble, improve efficiency. Horizontal knife adopts hydraulic feeding, up and down lifting adopts guide column type contact surface, more reasonable and stable. The equipment has the features of high cutting efficiency, high slice precision, high stability, simple operation, good flatness of the cut out plate, etc. It is suitable for granite, marble, large barren material layered cutting

Technical Parameters

|

name

|

unit

|

DFD-S1600 |

DFD-S1800 |

DFD-S2000 |

|

Maximum blade diameter

|

mm | 1600 | 1800 | 2000 |

|

Maximum processing length

|

mm |

4000 | 3800 | 3600 |

|

Maximum processing width

|

mm | 2200 | 2200 | 2200 |

|

Main machine lifting stroke

|

mm | 1350 | 1350 | 1350 |

|

Around Itinerary

|

mm | 750 | 850 | 950 |

|

Horizontal cutting saw blade diameter

|

mm | 400 | 400 | 400 |

|

water consumption

|

m³/h | 10 | 10 | 10 |

|

Cutting motor power

|

kw | 15 | 15 | 15 |

|

Main motor power

|

kw | 75/90 | 75/90 | 75/90 |

| Total power | kw |

100/115 |

100/115 | 100/15 |

| Weight | kg | 13000 | 13000 | 13000 |

|

Overall dimensions (L*W*H)

|

mm | 8000*4000*3700 |

8000*4000*3700 |

8000*4000*3700 |

Machine Details

Performance Features

High lumbering rate:Replacing the traditional rough mining manual unloading board, unloading board cuttings are smooth, not easy to break, will not cause sheet waste.

High cutting accuracy:The body structure is sturdy and thick, and adopts linear guide rails to move, which makes the cutting smoother, more accurate, and the board surface more flat.

low energy consumption:Adopting high-efficiency energy-saving motor, with the same output, energy consumption is lower, and the comprehensive cost can be reduced by about 15~20%

good stability:Equipment motors, bearings, hydraulic accessories, etc. are used in domestic and foreign first-line brands, more stable operation.

Introduction Edge cutting machine is suitable for trimming and shaping imported rough materials and irregular stones. Users can choose ordinary workbench or electric rotary work...

We provide customization product please contact our sales with detail requirement, we will manufacture machine accordingly: Special customization size: Cross beam length: 6500-1050...

The block cutter machine is mainly for granite and marble, it adopts multi-disc and PLC programmable control and man-machine interface, combined with a super-precision rotary encod...

The block cutter machine is mainly for granite and marble, it adopts multi-disc and PLC programmable control and man-machine interface, combined with a super-precision rotary encod...

We are able to provide stone machine solutions to our customers in a timely and efficient manner....

(1)Warranty: One year warranty for machines, 6 month for scharger and other accessories. (2)Please send back the defective goods which are within the warranty p...

we can production kerbstone cutting machine,infrared stone cutting machine, bridge saw machine, stone polishing machine, stone grinding machine,stone chamfering...

When using block cutter for cutting, it has high efficiency and stable cutting quality, which can greatly increase production speed and reduce material waste, and is very suitable for large-scale production.2024-07-22

The Stone Block Cutting Machine has significantly reduced our lead times and improved overall workflow efficiencyMr. Desmond John 2024-06-04

This block cutting machine is efficient and precise, easy to operate, which greatly improves production efficiency, reduces material waste, and greatly meets our production needs.Yonas Alem 2024-07-27