Price:

Brand Name: DAFON

Model Number: DFLSX1200-13S

Power: 55KW&22KW

Application: kerbstone, roadside stone, cobblestone and tombstone

Weight: 10T

Place of Origin: CHINA.

Trading Method: FOB/CIF/EXW Xiamen Port

Certification: CE, ISO

Minimum Order Quantity: 1 SET

Delivery Time:90 Days

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Introduction of Kerbstone Cutting Machine

Granite kerb stone cutting machine is mainly for cutting slab width about45cm, the machine cut with10-14pcs of blade at the same time which will dramatically increase cutting speed and overal output, daily capacity can reach 30-35m³/20h.The machine is widely used for kerbstone, roadside stone, cobblestone and tombstone etc.

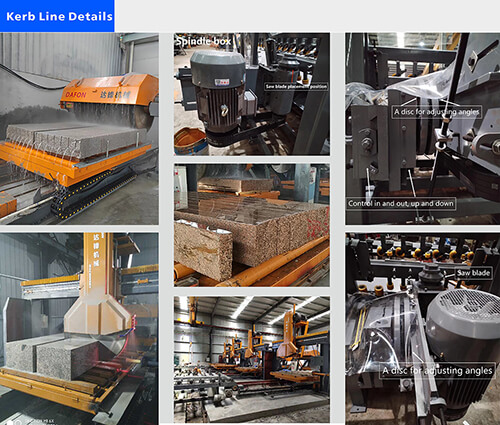

Component of Kerbstone Cutting Machine Line

1.Machine Parts:

The kerbstone cutting machine line includes one slicing machine(DF1200-12S) and one edge cutting machine(DF1200-1S), The worker loads a thick slab onto the slicing machine with a crane, and after the slicing machine finishes cutting, the roller on the worktable hydraulically lift up and transfer the stone to the next edge cutting machine.

The edge cutting machine has hydraulic pushers to push all the stones with blade gaps tight and together to ensure a precise cutting. After that, the cutting process is finished and ready for packaging.

2.Electrical Part:

The machine uses a Mitsubishi PLC control system, SIEMENS water proof button, Omron relays, etc, the machine is equipped with a remote control, so the worker can both use the controlling cabin or remote control during operation.

Machine Details

Special Features:

1. no cement foundation needed, easy installation and shipment(40'HQ).

2. the main shaft adopts high-frequency modulation treatment, which will be more durable and wear-resistant.

3. kerbstone cutting machine uses a main spindle and a vice spindle to seal all saw blades together which can ensure the machine is stable while cutting hard granite.

4. it uses a simple program of movement on the controlling box, easy to set, operate, and maintain.

5. kerbstone cutting machine adopts two hydraulic pillars(a set of hydraulic systems) on both sides of the machine to ensure the strength of cutting spindle lifting up and down.

6. Unlike traditional stone cutting, it dramatically increases productivity and reduces labor cost and power consumption and it consumes less diamond segment per cubic meter of production compared to the traditional cutting machine.

7. Cast iron is adopted in the main frame of the machine to make the machine more stable with less chance of vibration under the operating conditions.

8. The regular worktable length of the shaft is 1.6m(1.8m optional)

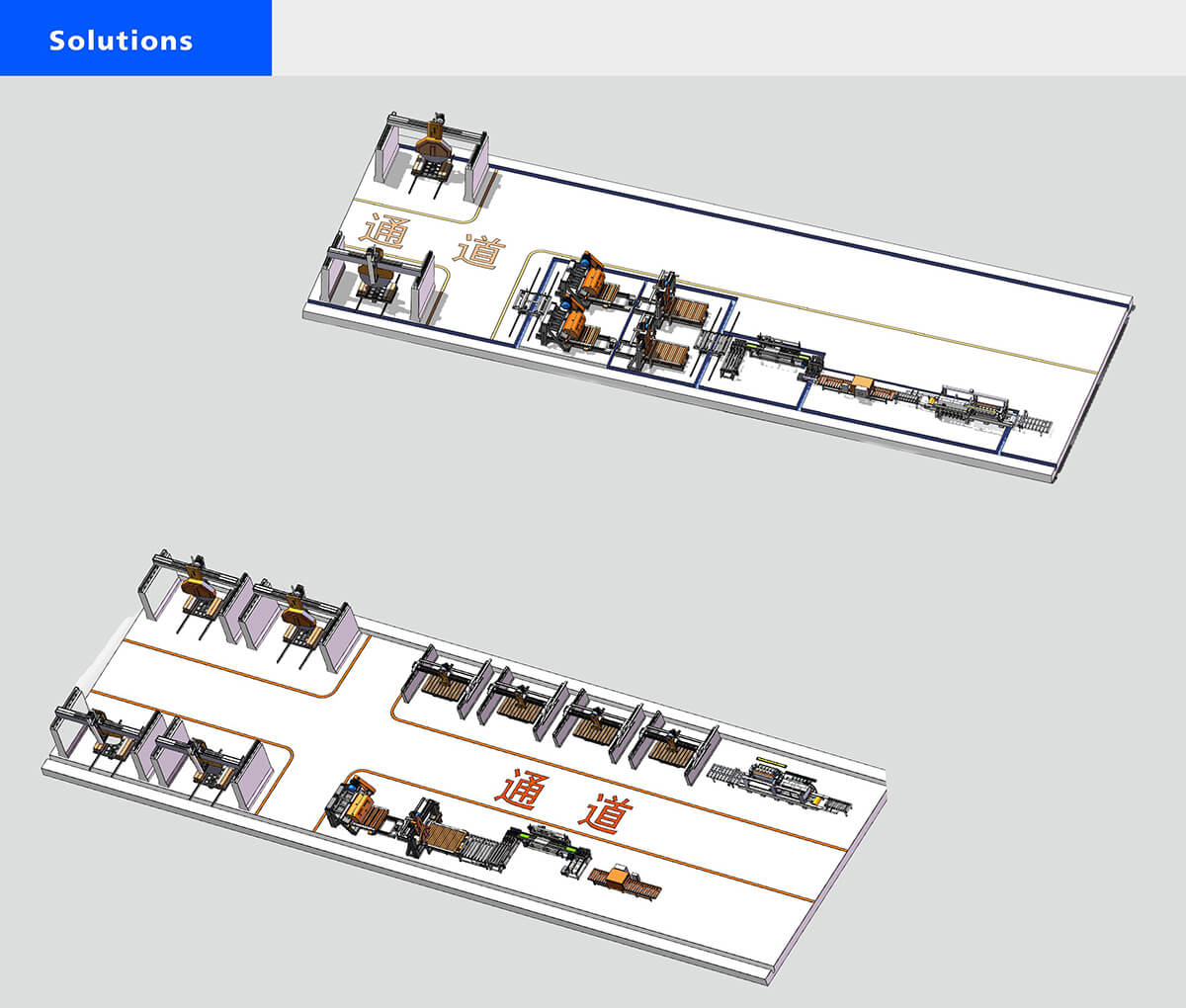

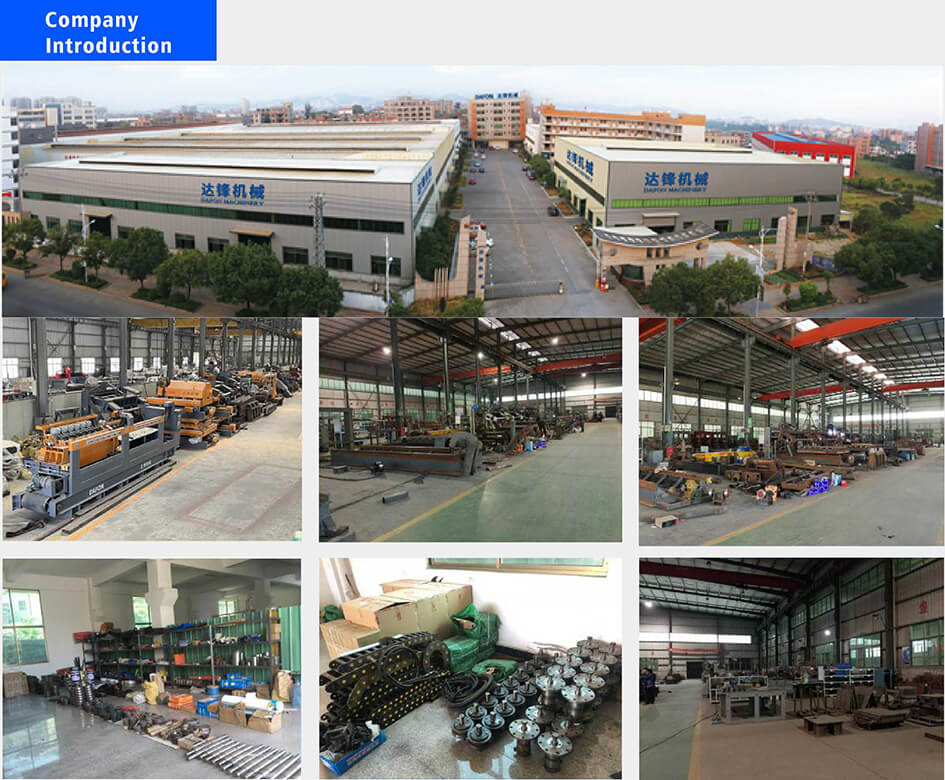

Manufacturing Workshop

Use scenarios of kerbstone cutter

What's the benefit of using kerbstone cutting machine?

1. Segments saving: the machine uses a multi-blade cut at the same time, every down cut is about 3-5mm(depending on stone and segment), which saves segment consumption.

2. Labor saving: the entire machine line only needs one worker to attend to it, the machine adopts rollers to transfer stone and sensors for automatic stop and operation.

3. Workshop space-saving: compared to other cutting methods, the machine needs only 12*5m space when producing the same capacity.

4. high-standard products: mechanized setting, the product is cut according to the customized cutting plan, and the size of the cut finished product is the same. Compared with manual or semi-automatic cutting, the error is small

5. Lower Investment: a roadside stone assembly line: including an edge cutting machine a stone slicing machine, a loader, and an unloader machine, The same cutting efficiency requires multiple stone cutting machines, so under comparison, the total equipment investment is small.

6.More Safety: The assembly line form solves the problems of loading and unloading materials and finished product transportation, and further reduces the risks of stone falling and being injured during manual transportation.

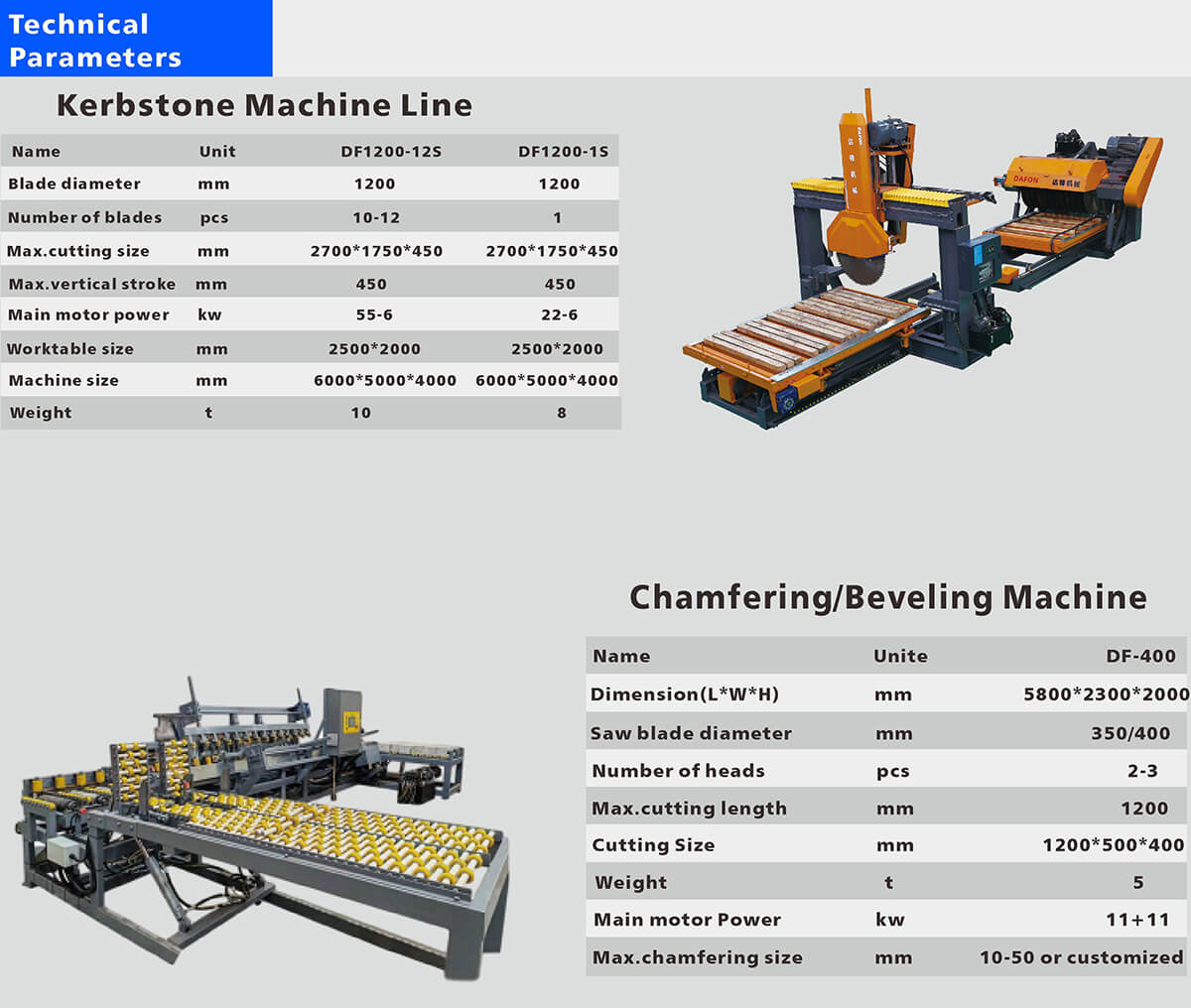

Technical Date

|

Complete Machine Line (1 Edge Cutting Machine + 1 Slicing Machine) |

|||

|

Slicing Machine DF1200-12S |

Edge Cutting Machine DF1200-1S |

||

|

Dimension |

6000×3000×2800mm |

Dimension |

6000×4000×4500mm |

|

Diameter of blade |

1200mm |

Diameter of blade |

1200mm |

|

Number of blades |

12pcs |

Number of blades |

1pcs |

|

Max.cutting size |

3000×1800×450mm |

Worktable size |

2500×1800mm |

|

Worktable size |

2500×1800mm |

Working length max |

2500mm |

|

Weight |

10t |

Max.vertical stroke |

600mm |

|

Max.cutting depth |

450mm |

Weight |

9t |

|

Main motor power |

55kw-6 |

Max.cutting depth |

450mm |

|

Max.vertical stroke |

600mm |

Main motor power |

22kw-6 |

|

It produces about 30-35m³ of stone every day (24h) and covers a total space of 12m*5m. |

|||

The stone edge chamfering machine can be combined with an above-cutting machine as a whole line for kerbstone cutting machine cutting, only 4 workers are needed from loading to packaging of the finished products.

FAQ:

1.What is the output of using a kerbstone cutting machine?

The output is related to the hardness of the stone and the sharpness of the cutter head. There will be a floating value, but a normal day is about 30 cubic meters.

2.What is the area occupied by the kerbstone cutting machine?

One set is about 80 square meters

3.can you accept customized service according to our actual needs?

of course, we have the ability to provide customized service, We have a dedicated R&D technical team and rich customization experience

4.How thick can a kerbstone cutting machine cut?

our kerbstone cutting machine cuts stone slab width above 50mm

5.How much does a kerbstone cutting machine cost?

Depending on your needs, need a complete line, or just need a slicing machine or an edge-cutting machine, whether you need to pair it with a stone edge chamfering machine, curb cutters can cost anywhere from a few thousand dollars to tens of thousands of dollars. contact us to get quote

6.How do I know if I need a curb cutter?

There are some factors that affect whether you need it

Stone thickness: stone with a thickness between 10 and 45 cm

Work efficiency: whether work efficiency needs to be improved, whether the project is urgent, whether working hours need to be shortened

Cutting accuracy: whether the cutting error is large and the degree of product standardization is low

Labor costs: to reduce labor wages to reduce overall costs

Site area limitation: No matter whether the processing site area is small or not, multiple machines and equipment cannot be enlarged.

7.Can a kerbstone cutting machine cut other types of stone?

Yes, many kerbstone cutting machines can be used to cut other types of stone, such as granite, marble, limestone and cement.

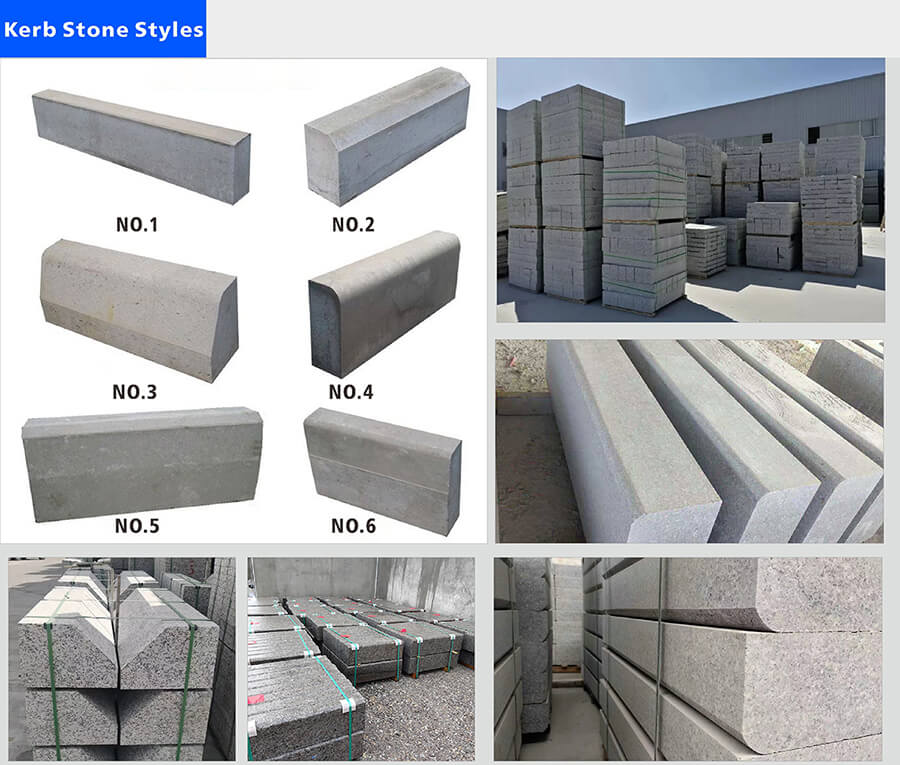

U-shaped Kerb stone: suitable for sidewalks or public squares, etc. Its curved design helps improve pedestrian safety and comfort. ...

T-shaped Kerb stone: often used in traffic islands, pedestrian bridges and other places to prevent vehicles from crossing illegally. ...

L-shaped Kerb stone : suitable for road edges, which can effectively guide the walking direction of vehicles and pedestrians. U-shaped Kerb stone : suitable for side...

Introduction of kerbstone chamfering machine The chamfering machine adopts an enlarged frame design, which is sturdy and durable, ensuring excellent performance in long-term use. ...

Introduction This kerb stone flaming machine is specially developed for processing the burned surface of curbstone. It uses flame spraying technology to form a rough burned su...

Machinepart The machine line included one slicing machine(DF1200-12S) and one edge cutting machine(DF1200-1S), worker load thick slab to the slicing machine with a crane, after s...

The advantage of using a kerbstone machine is its efficiency and precision. It can cut the kerbstones quickly and accurately, making it suitable for large-scale production.2024-07-22

This cutter saw is powered by a 55kw motor that delivers plenty of power for cutting through even the curb stones and thick slabs. It also has a 1200mm blade that can cut up to 450mm deep. I was able to use this saw to quickly and easily cut a variety of shapes and sizes of curb stones.Mr. Pejman 2024-06-22

The curb stone cutter from Dafon Machinery exceeded my expectations with its precise cuts and robust build. It has significantly improved our workflow efficiency and is highly recommended!2024-07-16