After the stone blocks material is processed into a slabs , it is necessary to deal with its surface. Stone surface treatment method has a variety of methods, such as grinding, grinding matte, fire, water, pickling, etc., which uses the most methods is grinding and polishing, in this paper we exp...

Classification of Stone Countertop Stone countertop mainly include: granite countertop, marble countertop, sandstone countertop, slate countertop, limestone countertop and quartzite countertop, of which the mainstream is granite and marble countertop, and the number of production and applicatio...

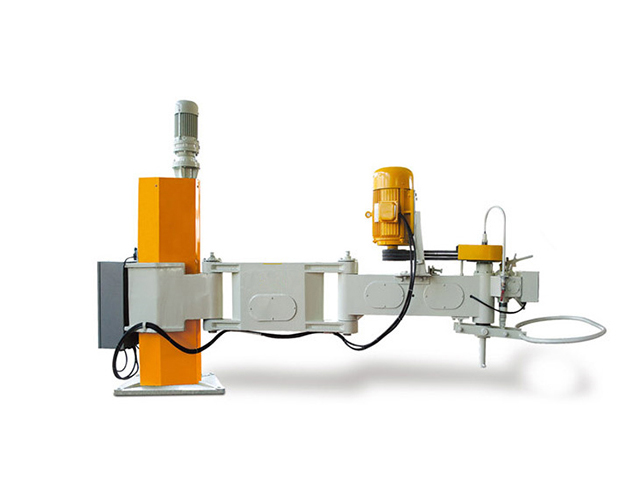

1.ProductIntroduction: Automatic granite polishing machineis suitable for polishing Granite slabs or strips. Use the PLC system and liquid crystal display screen menu offer intelli...

S tone polishing machine is suitable for polishing Granite slabs or strips. Use the PLC system and liquid crystal display screen menu offer intelligent control. Establish Auto-dodging ...

ProductIntroduction: Marble granite stone polishing machineis suitable for polishing Granite slabs or strips. Use the PLC system and liquid crystal display screen menu offer intelligen...

Urban roads: Kerb stones play a protective and guiding role in the construction and maintenance of urban roads. Sidewalks: Curbs can define the boundaries of sidewalks, providing a...

Give the space a stronger sense of wholeness and high-class atmosphere...

Automatic marble stone grinders offer several advantages over traditional manual grinders, including: Increased Efficiency: An automatic marble stone grinder can process large amou...