Introduction. 1. Raw Material Selection. 2. Cutting and Shaping. 3. Surface Finishing. 4. Edge Profiling. 5. Quality Control. 6. Packaging and Logistics. 7. Automation and Integration. 8. Sustainable Practices. Conclusion....

Introduction. 1. Machine Setup and Safety Precautions. 2. Blade Selection and Maintenance. 3. Operational Guidelines. Conclusion....

Introduction. 1. Cutting Capacity and Power. 2. Blade Quality and Type. 3. Automation and Control Features....

Introduction. 1. Cutting Capacity. 2. Power and Speed. 3. Precision and Control. Conclusion....

Introduction. Factors to Consider. Types of Granite Tile Cutting Machines. Conclusion....

Granite edge cutting used to be a difficult and time-consuming task, but our machinery has made it easier than ever before. With our advanced equipment, you can achieve precise cuts in a fraction of the time it used to take. Not only does this save you time and money, but it also ensures a higher q...

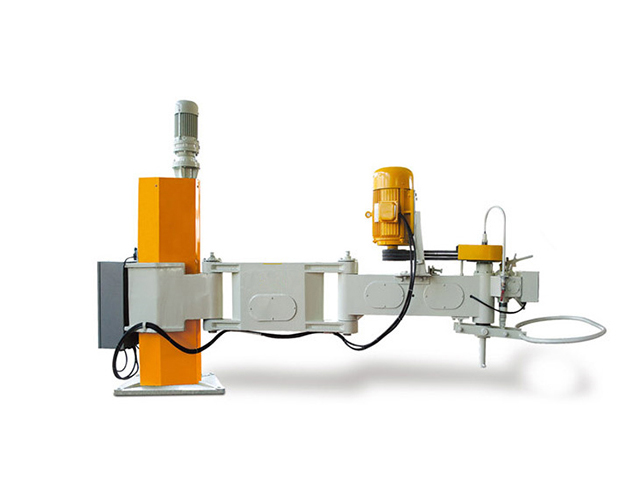

Introduction to Granite Edge Cutting Machine If you are looking for a high-performance machine for cutting granite edges, then the Granite Edge Cutting Machineis an excellent option. This machine is designed to provide efficient and precise cutting of granite stone, making it an essential tool f...

Introduction to Granite Cutting and Polishing Machine Granite cutting and polishing machinesare specialized equipment used to cut and polish granite and other natural stones. These machines come in different sizes, models, and functionalities, depending on the type and quantity of stone material...

Automatic Granite Polishing MachineTechnique Description : I.Suitable for the surface polishing granite/marble II.Using PLC intelligent control system and through the LCD touch screen...

S tone polishing machine is suitable for polishing Granite slabs or strips. Use the PLC system and liquid crystal display screen menu offer intelligent control. Establish Auto-dodging ...

The introduction ofmarble polishing machine Stone polisher machineis suitable for polishing Granite slabs or strips. Use the PLC system and liquid crystal display screen menu offer ...

Give the space a stronger sense of wholeness and high-class atmosphere...

Doors and Windows : stone window sills, door frames, window frames and other shaped processing, so that the stone doors and windows are more ornamental ...

Repair The Surface of Stone In the face of a broken or damaged stone surface, Stone splitting machines can also be transformed into a restoration tool, through fine cutting and polish...