Regular Cleaning. Lubrication and Inspection. Calibration and Alignment....

1. Cleaning and Lubrication. 2. Blade Maintenance. 3. Electrical and Mechanical Components....

1. Regular Cleaning and Inspection. 2. Lubrication and Calibration. 3. Safety Measures and Operator Training....

The stone cutting bridge saw was developed on the basis of hand-operated cutters and hydraulic cutters and is mainly used for cutting granite and marble slabs. 1.Advantages of the bridge saw cutting machine The stone cutting bridge ...

Machine details Motor: Eagle brand or Mindong brand Hydraulic station: seven ocean hydraulic system from Taiwan cement foudation or metalic foundation Worktable: size: 3000*2...

The machine is controlled by a microcomputer, The matching table can be rotated 360° in the horizonta plane, 45° a positioning(jumpable angle positioning), 85°flap. Precision manufac...

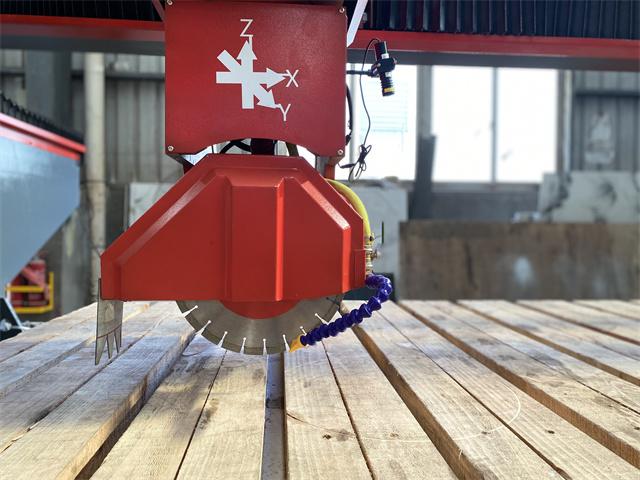

The bridge saw machine adopt cast iron on the main part of machine body ensure stability while cutting The cutting speed is controlled by inverter to achieve stepless adjustment, the he...

A blade block cutter saw machine is a tool commonly used in the construction industry for cutting blocks of materials such as stone, concrete, and brick. Here are some of the applicati...

A granite stone block cutting machine is a specialized industrial tool used to cut large blocks of granite into smaller pieces or slabs of desired size and shape. This machine typically...

Give the space a stronger sense of wholeness and high-class atmosphere...