I. Introduction

What is granite stone and uses

Granite, also known as granite, is an igneous rock, generally formed from volcanic materials, such as magma, while marble is a metamorphic rock, which is naturally metamorphosed from one stone into another under high temperature and high pressure environments and the mixing of minerals. Stone formation. Granite is a hard stone. Its rock quality is hard and dense, and it is suitable for use as building materials.

Hard, durable, waterproof and beautiful,

Building materials: Granite is commonly used in building exterior walls, floors, countertops and decorations.

Monuments: Granite is often used to create tombstones and other monuments.

Sculpture: Granite is often used to create sculptures and other works of art.

Kitchen Countertops: Granite is a popular kitchen countertop material because it is strong, durable, and easy to clean.

Flooring: Granite floors are durable and easy to maintain.

Pavement: Granite pavement is durable and can withstand vehicular and pedestrian traffic.

What are granite block cutting machines?

Granite block cutting machine is a mechanical equipment used for cutting granite blocks. Granite blocks refer to unprocessed granite blocks that are mined. Granite block cutting machines are usually used to cut granite blocks into the required size and shape for subsequent processing.

Due to the wide range of application fields of granite stone, and the hardness of granite brings challenges to processing, which requires specialized granite processing for cutting and processing, granite block cutting machines play a vital role in the stone industry.

II. Types of Granite Block Cutting Machines

Multi balde Block Cutting Machine:

It is suitable for cutting large granite blocks and has the characteristics of fast cutting speed and high efficiency. However, the cutting accuracy is low and it is easy to cause damage to the stone.

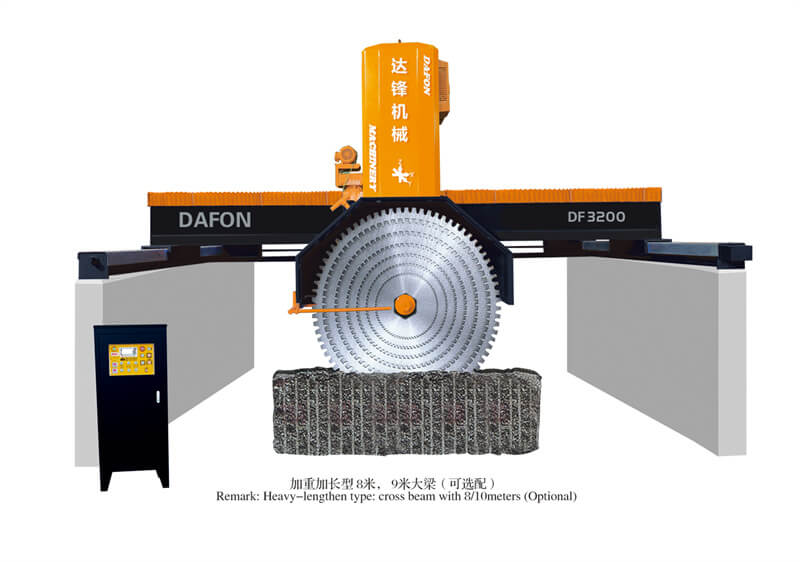

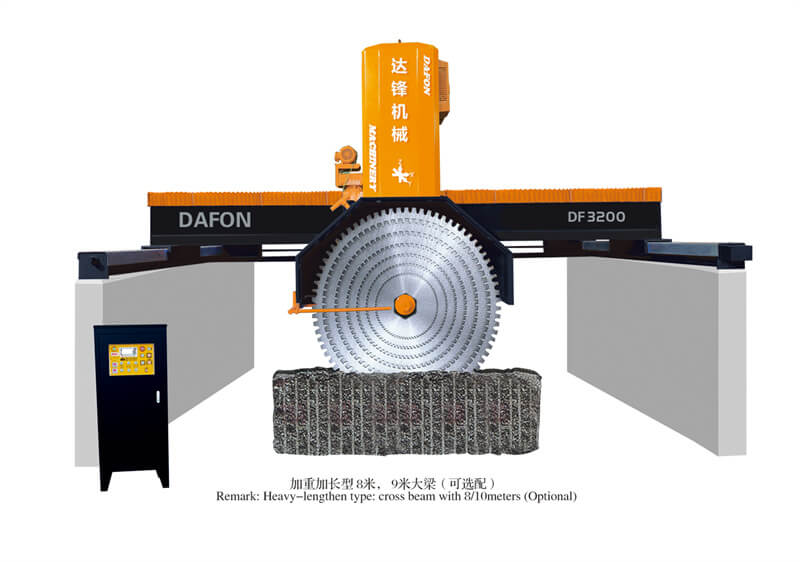

Granite Bridge Saws

It is suitable for cutting small and medium-sized granite blocks and has the characteristics of high cutting accuracy and wide applicability. However, the cutting speed of the bridge cutting machine is slow and the technical requirements for the operator are high.

CNC Water Jet Cutter

The water jet cutting machine is suitable for cutting high-precision and complex-shaped granite blocks, and has the characteristics of high cutting accuracy and no pollution. However, waterjet cutting machines have slower cutting speeds and higher costs.

Granite Laser Cutting Machine

The laser cutting machine is suitable for cutting high-precision, complex-shaped granite blocks. It has the characteristics of fast cutting speed, high precision, and can cut complex shapes. But the cost of laser cutting machines is very high.

III. Factors to Consider When Choosing a Granite Block Cutting Machine

A. Size and thickness of granite blocks: Different specifications and sizes of granite blocks require different types and sizes of cutting machines. Make sure the cutting machine you choose can accommodate the size range and thickness requirements of the granite blocks you need to process.

B. Required cutting speed and accuracy: Determine the required cutting speed and accuracy level based on production needs. Some applications may require higher cutting speeds, while others are more concerned with precision and quality of cuts.

C. Budget: Cutting machines come in a wide range of prices, from basic to high-end models. Choose the best cutting machine based on your budget constraints to ensure you get the best performance and quality within your budget.

D. Level of automation: Consider the degree of automation required in the production process. Some cutting machines have higher levels of automation, reducing manual intervention and increasing production efficiency. Choose the right level of automation based on production needs and budget.

To sum up, when choosing a granite block cutting machine, you need to comprehensively consider factors such as the size and thickness of the granite block, the required cutting speed and accuracy, the budget, and the level of automation to ensure that the most suitable equipment is selected to meet production needs.